Caldas’ Turnkey Crusher Wear Parts Solution

Caldas’ approach transformed reduced Wear and Downtime in a High-Impact application at a gold minining operation in Southern Africa. The company supplied a redesigned set of swing and fixed jaws in a high-impact resistant 20Mn2Cr composition with a deeper profile and additional tooth support.

At Caldas Engineering, our turnkey wear parts solution goes beyond supply. We partner with clients to extend the lifecycle of their crushing equipment by offering:

- Precision-engineered wear components tailored to site-specific applications

- Metallurgical consulting to match manganese grades with material feed

- Wear pattern analysis and reporting

- Supply chain and inventory planning to eliminate downtime

- Technical support for our parts.

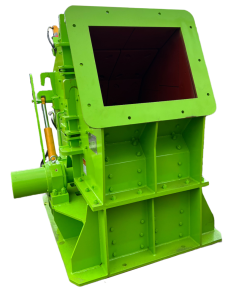

Case Study: Reducing Wear and Downtime in a High-Impact Application

Client Challenge:

A gold mining operation in Southern Africa was experiencing excessive wear on their primary jaw crusher swing and fixed jaws – requiring change-outs every 6–8 weeks. This frequent maintenance was disrupting throughput and causing unplanned production halts.

Caldas’ Approach:

Our engineering and field service teams conducted a full wear audit, including:

- 3D scanning of worn components

- Feed material and throughput analysis

- Review of crusher stroke, nip angle, and choke feed consistency

From this, we determined the existing liners were underperforming due to an unsuitable manganese composition and profile for the high-impact quartzite feed.

Solution & Installation:

We supplied a redesigned set of swing and fixed jaws in a high-impact resistant 20Mn2Cr composition with a deeper profile and additional tooth support. Installation was coordinated with the client’s maintenance shutdown, with our technicians on-site to supervise and optimise fitment.

Results:

- Wear life extended from 6 – 8 weeks to over 8 – 10 weeks

- Crusher availability improved by 22% over the quarter

- Reduced liner-related stoppages, increasing downstream plant stability