“The MVR mill for dry application is a proven equipment over many decades in industry applications for grinding of hard to medium-hard materials. More than 3000 Gebr. Pfeiffer vertical roller mills have been installed in the cement, lime, gypsum, solid fuels-industry and in industrial minerals.”

Rising power costs as well as construction and consumable cost paired with declining grades and the need to process harder ores require a change in comminution equipment selection. Reduced energy and water consumption are mandatory for enhanced sustainability. A dry grinding system that is well known and capable of achieving this is the vertical roller mill.

Vertical roller mills are traditionally air-swept mills. The material being ground is dried, if necessary, and transported by a stream of air during comminution to the classifier mounted on top of the mill. Those continuous operating mills are used for flexibly adaptable comminution and simultaneous drying very hard to medium-hard materials. The modern mill type is known in many industries such as cement, lime and gypsum industry as well as for grinding of solid fuels for power generation.

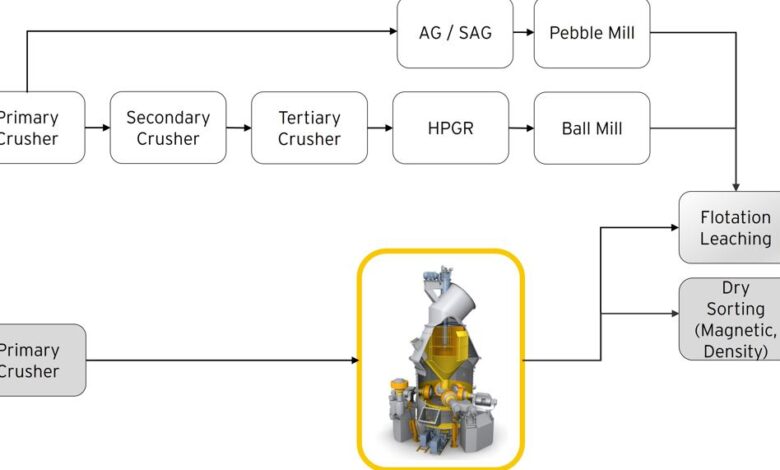

Dry grinding technology with vertical roller mills gives a substantial benefit in energy savings: the energy consumption is about 30 to 40% lower than that of traditional mill systems used in the mining industry The vertical roller mill is a highly flexible machine that simultaneously grinds, dries and classifies. Dry grinding is able to deliver a uniform size reduction with a narrow particle size distribution. The achievable product liberation size is in the range between P80 of 1 mm down to P99 of 20 μm. The reduction size ratio of up to 1000 is very high compared to traditional systems. The secondary or tertiary crusher can then be omitted due to the large feed size capacity of the vertical roller mill (refer to Figure 1).

Start-up and shutdown of this mill type is much easier than in traditional milling. In today’s energy-constrained world the energy use can be managed much more easily with the flexibility of a vertical roller mill. Also, dry grinding is the pre-condition for subsequent downstream dry separation in combination with reduced water consumption.

The MVR mill for dry application is a proven equipment over many decades in industry applications for grinding of hard to medium-hard materials. More than 3000 Gebr. Pfeiffer vertical roller mills have been installed in the cement, lime, gypsum, solid fuels-industry and in industrial minerals. This flexible equipment reduces energy consumption to enhance sustainability and improve the circuit’s overall emissions profile also in ore processing. Depending on the ore body the grind size adjusted for coarse particle flotation (CPF) could reduce further grinding energy, produce coarser tailings and decrease the footprint of flotation circuit and solid-liquid separation.

The dry grinding of ore in the MVR mill results in optimum grind size and increased liberation. In the rougher stage downstream the MVR sorting and separation of tailings and grade material takes place with the target to produce tailings with very low content of grade material. The amount of material to be concentrated further downstream shall be reduced as much as possible.

Gebr. Pfeiffer’s MVR vertical roller mill technology offers the highest power density in the industry. The compact nature of the machine with everything included in an integrated design (including a classifier), is complemented by up to 18 MW of operating power, providing production rates of up to 7,000 t/h with a single mill.