Wear Parts and Mill Liners for African Mining Operations

Extending Wear Life, Increasing Availability

COVID-19 pandemic lockdowns have resulted in disruptions to the global supply of components and equipment. Recognising this concern, Growth Steel assures its existing and potential clientele in the Global mining sector that it is well-placed to meet the demand for wear parts and lining for their grinding and mineral processing equipment. As mining companies are ramping up production to take advantage of high commodity prices, mining companies need high equipment availability.

“Increased Performance, Availability and Lower Maintenance Costs” is the aspiration of every plant engineer in companies involved in the grinding and processing of minerals. But in reality, attaining this goal is not a given.

More often than not, downtime to equipment due to component failure is encountered, and unfortunately, when least expected. In most instances, this is down to lapses during the procurement processes. Because of this, Growth Steel tells mining companies that procurement of essential products like wear parts and mill liners should be based on informed decisions. Growth Steel urges companies to partner with suppliers that have built a rich track record of consistently providing reliable solutions.

“At the outset, a mining company has to establish whether or not the identified supplier can furnish them with a solution that can guarantee long spells of uptime of equipment. This is important as, unfortunately, some organisations supply products and leave clients to their own devices when it comes to services and technical support,” explains Chris Muller, Head of Technical Sales at Growth Steel Africa.

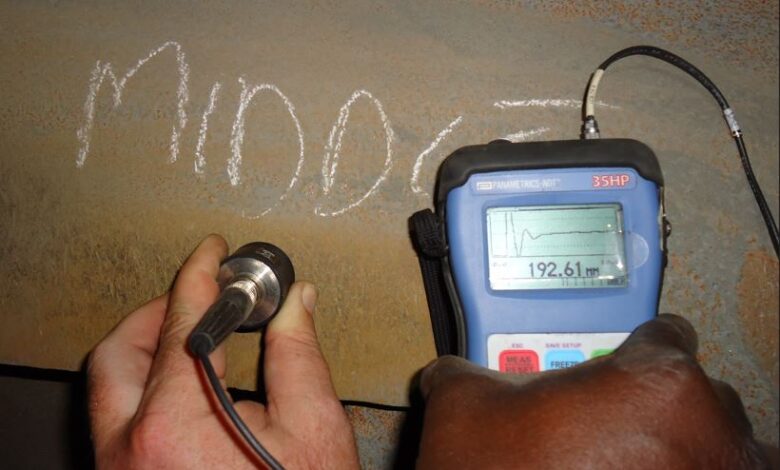

Muller affirms that Growth goes to great lengths to find solutions to complex challenges in wear parts and mill liners, recognising the impact of downtime on productivity in a mill circuit. “We are well-placed to answer to any call from a client, well-resourced with the necessary expertise and relevant technology,” he pronounces, referencing the organisation’s turnkey solution that delivers a wide range of products, constant innovation, devotion to excellence, and global footprint and production capacity.

Wide range of products

Employing the latest in simulation software and manufacturing techniques, Growth Steel produces a wide range of high-quality liners and wear parts for grinding equipment components. Its products are specifically designed to extend equipment wear life, increasing availability for production.

Particularly worth mentioning is that there is “no one-size-fits-all” as every design is bespoke to a particular client’s application needs. Liner development is done in close cooperation with the plant personnel, and a tailored solution will be implemented to compliment the mill performance and availability.

High-quality liners

Growth Steel’s lining products are made of rubber and steel to cater for the diverse requirements of mining companies. Muller specifies that this is in recognition of the complementary functions of steel and rubber liners. “We understand how each of these types of products (steel and rubber liners) works best for specific mill applications and how your business can benefit from them.”

- Rubber mill liners

Remarkably, Growth Steel Africa has replicated the know-how honed over the years in designing and manufacturing steel lining in rubber lining. In the manufacture of rubber mill liners, it utilises uniquely developed polymer compounds.

Muller demonstrates the process of delivering the correct rubber liner to the client involves: “First of all, to settle on a material grade for the most ideal for a task, we first determine where a milling application requires impact toughness, abrasion resistance or balance. Then, a decision is reached on the chemistry and microstructure properties to be produced within the quality liners.”

Growth Steel utilises its best-equipped laboratory for testing and developing differentiated rubber compounds to suit clients’ specific operational requirements. All components for our composite liners are manufactured in-house. The tracks are sourced from the worlds best aluminium suppliers to guarantee overall quality and uniformity. Generally, Growth Steel offers a full range of both rubber and steel liners for application in the following milling circuit equipment: SAG Mills, AG Mills, Primary and Secondary Ball Mills, Regrind Mills and Scrubber Mills.

- Wear parts for grinding mills

The delivery of relevant excellent wear parts is another field where Growth Steel has excelled, establishing itself as one of the world’s preferred suppliers, underscored by the use of unique products and a wide range of products.

Poly-steel, otherwise known as “composite” liners, combining the best properties of rubber and steel in one product, is used to create the most wear-resistant and high-performance components. Lighter than full steel, poly-steel is faster and safer to install while contributing to higher productivity.

Moreover, Growth Steel offers the client a wide range of steel inserts, from chrome-moly and white iron inserts to commercially proven high-wear and abrasion-resistant steel plating. Each of its casting designs can include multiple casting profiles, face angles and weights specifically tailored to suit your grinding conditions.

Comprehensive turnkey solution

Having observed the impact of unreliable suppliers on equipment availability for years, Growth Steel recognises the value of the convenience of accessing everything under one roof. And so, it offers a comprehensive turnkey solution that involves design, manufacturing, as well as sustained support with continuous consultations to achieve the optimal satisfaction

Uncompromising devotion to excellence

Muller acknowledges that with different products flooding the market, sometimes clients might find it difficult to discern quality from mediocre products. However, the quality of Growth Steel’s products speaks for itself in terms of durability and cost-effectiveness, he states.

“What makes our products stand out is an uncompromising devotion to excellence in all product development, practices and procedures, following ISO standards. The culture of service excellence is entrenched in our processes.”

Constant innovation, product relevance

Growth Steel owes its longevity in a highly competitive market to constantly keeping pace with industry requirements and adapting its solutions correspondingly, says Muller. “Customer needs are changing in accordance to the demands the operating environment places on their respective businesses. The main objectives are cost containment, increasing safety, reducing the environmental impact of their operations, and improving efficiency. Thus, we are constantly seeking ways to meet these through innovative products, services and solutions.”

Global footprint and adequate capacity

In the current environment, due to the covid-19 pandemic, the supply chain has been disrupted, causing costly downtime to equipment. But Muller says that, through drawing on its capacity and global footprint, Growth Steel has forestalled this challenge, guaranteeing the certainty of supply.

Growth Steel Africa is part of Growth Steel Group, an established world leader in service excellence for the design and manufacture of mineral processing wear solutions that was established in 1989. Growth Steel has a manufacturing capacity of up to 65,000 tons of mill liners a year for mining industries.

What is more, headquartered in Medan – North Sumatra, Indonesia, Growth has branches located strategically worldwide in Perth, Brisbane, South Africa, Ghana, Peru, Chile and China. All in all, for mining companies looking for a reliable provider of wear protection solutions for grinding mills, Muller recommends clients to look no further than Growth Steel: “For relevant experience and expertise in mill lining you can count on us.”