SEW-EURODRIVE advances predictive maintenance for modern industry

How real time asset intelligence is reshaping maintenance strategies across sectors

Predictive maintenance has become a practical requirement for industrial operations looking to reduce downtime, manage maintenance costs and improve energy efficiency.

What was once viewed as an emerging technology is now widely adopted across sectors that depend on reliable equipment performance, from mining and automotive manufacturing to agriculture, ports, and food processing.

According to Willem Strydom, Business Development Manager for Electronics at SEW-EURODRIVE, the shift is being driven by demand for deeper operational visibility and faster access to actionable data.

“Customers increasingly want deeper, real-time insights into their operations and DriveRadar provides exactly that through an ecosystem of intelligent sensors, edge devices and cloud-based analytics offering complete operational visibility.”

Traditional maintenance methods such as periodic plant surveys are increasingly challenged by today’s dynamic production environments. Werner Engelbrecht, Works Manager for Megatronic at SEW-EURODRIVE, explains that these surveys quickly lose relevance as equipment is repaired, replaced, or expanded.

In contrast, DriveRadar automatically records every new asset added to a plant, creating a continuously updated and accurate overview of operational equipment.

Beyond visibility, the real value of predictive maintenance lies in its ability to prevent failures. Engelbrecht notes that operators who respond to the system’s insights can avoid major breakdowns altogether, while also reducing the need for repetitive physical inspections.

This allows maintenance teams to redirect their efforts toward more strategic tasks rather than routine checks.

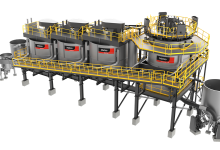

One distinguishing aspect of DriveRadar is its use of SEW-EURODRIVE’s integrated drivetrain components rather than relying solely on external sensors. Strydom points out that the company’s frequency inverters function as highly accurate multifunction sensors, capturing data such as operating time, energy consumption, load, torque, and vibration related events.

Each inverter generates hundreds of parameters that feed into the system’s analytical models.

Additional motor and vibration sensors can be added where higher levels of detail are required. These provide data on temperature, ambient conditions, oil levels and ageing indicators, load changes and vibration signatures extracted from motor harmonics.

This information is combined to create a digital twin of each drivetrain. Using AI driven models, the system learns normal operating behaviour from commissioning onward. Deviations from this baseline are flagged early, supporting the identification of bearing wear, brake lining life, oil change intervals, structural faults, and inefficient load conditions.

The monitoring capability also extends to non-SEW EURODRIVE components, allowing entire applications such as conveyors or pick and place systems to be assessed.

Data accessibility is another important factor. DriveRadar supports deployment in the SEW EURODRIVE cloud, customer owned infrastructure, or local servers, and integrates with existing SCADA systems.

Maintenance teams can access reports and asset data via mobile devices, including in remote locations using GSM or SIM based communication, reducing the need for on-site inspections.

Supporting these technologies, SEW EURODRIVE has expanded its training offering, providing customers with access to on-site instruction as well as structured programmes through its Drive Academy in Johannesburg.

Excellent breakdown, I like it, nice article. I completely agree with the challenges you described. For our projects we started using lokando24.de and experts for our service,germanys top classified and directory growing site, well can i ask you a question regarding your article?