New wire rope lubrication method shows promise in South African Mining

Innovative techniques aim to extend rope life, reduce downtime, and improve safety in mining operations

Mining and industrial operations in South Africa are exploring a more efficient approach to wire rope maintenance with the Viper wire rope lubricator; a system developed in Australia over 15 years ago.

Initially designed for port applications, the device is gaining attention for its potential to improve rope longevity and maintenance efficiency in local mining operations.

“It really shines in the mining sector, particularly for six-stranded triangular mine winder ropes,” said Ronald Byrnes, business development manager at Lubrication Engineers (LE) South Africa.

Byrnes has been involved in establishing benchmarking standards for wire rope lubrication through LE’s Xtend team, a group of technicians specializing in assessing, applying, and monitoring lubrication systems.

Efficiency and Practical Impact

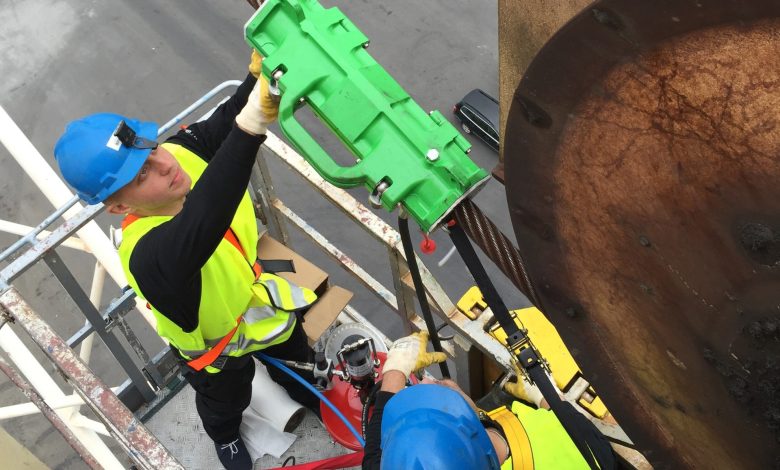

Maintenance teams often face significant downtime when applying lubricant manually. Traditional methods can require several hours of scrubbing, sometimes leaving machinery offline for more than a day. The Viper system allows operators to clean and lubricate ropes in a single pass, reportedly reducing this process to under an hour.

“It takes us very little time to set up, and it can run continuously, even changing pails of lubricants is done in real time,” Byrnes noted.

The device works by using compressed air to push lubricant into the rope strands at approximately five bar of pressure. Hinged collars and polymer composite seals with internal ridges help distribute the lubricant across the rope’s outer strands and valleys.

“The ridges inside it massage the lubricant into the rope, particularly the outer strands and the valleys between the outer strands of the rope, so that one gets a proper specified coating coverage of the rope,” explained Byrnes.

Safety and Longevity Considerations

Traditional lubrication methods can sometimes contribute to rope corrosion. According to Byrnes, “With ropes where we applied lubricant using the Viper I haven’t any instances of rust on ropes.”

The system also reduces safety risks associated with bitumen-based lubricants, which require high temperatures for application and can release toxic fumes.

Alternatives compatible with the Viper, such as LE’s Wirelife® Almasol® Coating Grease 452, are considered safer for maintenance personnel.

Industry Perspective

While the Viper requires initial investment, its proponents suggest it could result in lower long-term maintenance costs due to extended rope life and reduced downtime.

“For clients, success to date has also been measured on the return of investment over the long term through preservation and better use of maintenance expenditure,” Byrnes said.

LE South Africa represents Lubrication Engineers in Southern Africa and provides high-performance lubricants across a range of industrial applications, supported by technical expertise.

The Viper wire rope lubricator is now being assessed across multiple sites for its effectiveness and potential to set new standards in wire rope maintenance.