Innomotics drives innovation through digitalisation

Innomotics, an independent company recently spun off from Siemens AG, made a strong impression at the recent 2024 Electra Mining event, where its advanced drive solutions received widespread acclaim.

Following the event, Tim Walwyn, CEO of Innomotics South Africa, spoke with MINING BUSINESS AFRICA about the company’s strategy to leverage digitisation and deliver industry-leading, customised drive solutions across various sectors.

Walwyn emphasized that Innomotics represents a combination of innovation and engineering excellence, built on decades of experience in electric motor and drives. The company is dedicated to bringing cutting-edge technology and reliability to its clients, helping industries enhance operational efficiency through tailored digital solutions.

MBA: We were caught by surprise by the branding of Siemens’ drive technologies business portfolio to Innomotics, when one thought there was no need to fix what’s not broken. What necessitated this move?

TW: Innomotics is a way for us to really focus on innovation of our drive technology portfolio on top of the legacy developed by Siemens over the course of more than 150 years. As a standalone company, we have the freedom to be more agile and responsive to customer needs and evolving market trends, allowing us to focus on industries for whom motor and drive systems are key performance drivers, such as mining, utilities, oil and gas, and manufacturing.

MBA: How do you see industries benefiting from Innomotics ‘niche’ drive technologies speciality?

TW: For our customers, our technology focus means that we bring in-depth process and application know-how to the table. In conjunction with our broad range of products, this means we can partner with customers to develop the best possible solution to every challenge.

Our innovations lead to concrete performance advantages such as higher power density, greater availability, reduced emissions, and more optimal control. Increasingly important are the insights gained from smart products complemented by our INSPIRE IQ digital monitoring system, and even end-to-end digitalisation for the mining value chain through our DIGIMINE portfolio.

MBA: What opportunities has Innomotics identified as mining companies and other industries embrace the digitisation of conveyor automation?

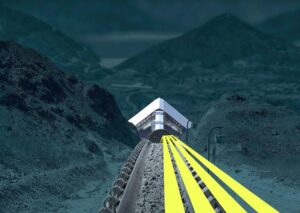

TW: As a full-service solution provider to the mining industry, Innomotics delivers electrical, drive-train, automation, and digitalisation solutions for mining plants, which gives us a unique insight into the performance of conveyor systems, and opportunities for their digitalisation.

Starting with the equipment, digital technologies enable us to monitor the electrical and mechanical performance of conveyor drive trains. At the next level, our process automation systems incorporate dedicated libraries for efficient operation of conveyor control and safety. We work closely with specialist suppliers of conveyor instrumentation to ensure that all information required for effective automation is available.

Of course, all of the data derived from these systems can be used as a basis for condition monitoring as a basic digital application. From our perspective, what is more interesting is that by building on this robust electrical and automation layer, we are able to derive concrete process optimisations through our DIGIMINE Digital Twin solution.

Digital Twin combines real-time data acquired from the operational conveyor system with advanced modelling of the physical performance of the machine itself and an understanding of up and downstream processes. Through this holistic view, it is possible to optimise not only the performance of an individual conveyor, but of the complete material flow system.

Examples of possible improvements include reduction of blockages, more consistent material flow into downstream processes, and increased throughput without the need for major mechanical changes.

MBA: Conveyor failure impacts productivity and maintenance costs. How does your IIoT digitisation, Inspire IQ, help address this challenge?

TW: In addition to our DIGIMINE Digital Twin offering for conveyor systems, Innomotics enables detailed IIoT monitoring of key drive system components through INSPIRE IQ, our platform for digital enhancement of motors and drives.

The INSPIRE IQ system collates and analyses multiple signals from a drive system in order to detect any change in the operational conditions that may signal a potential failure before it happens. Data acquired includes mechanical and electrical parameters, preventive maintenance actions, and environmental conditions.

This helps our customer service teams to advise customers of work that can be carried out during planned shutdowns and critical spares that need to be available. In a worst case, we are able to respond rapidly in case of a failure due to the system-generated alerts. This approach has directly prevented downtime incidents at several mining sites around the world.

MBA: Could you take us through the precise steps of what conveyor drive digitisation would entail for a greenfield mining project?

TW: Greenfield projects have the advantage that design alternatives can be explored in order to identify the best option at relatively low cost. Our Digital Twin solution can be used as a simulation tool to assist in the optimisation process.

It is important to build in the complete span of technologies that will allow for effective digitalisation from the outset in order to save costs down the line. A major advantage to implementing digitalisation during the engineering phase is that the availability of the Digital Twin system can dramatically improve commissioning performance and reduce ramp-up time, which can have a significant bottom-line impact on projects.

MBA: What about a brownfield project aiming to retrofit its drive systems?

TW: While each brownfield site presents its own challenge, there is still significant scope for digitalisation. We often recommend an incremental approach in these cases. For example, installation of Inspire IQ monitoring technology on the drive train can lead to improved availability with relatively low investment.

As a next step, the Digital Twin system can be applied to particular problematic machines or plant sections in order to improve the performance of obvious bottlenecks. Finally, the system can be expanded to cover the entire plant scope in order to assist operators to realise continuous performance improvements.

MBA: Ultimately, what would a mine benefit from engaging Innomotics as a conveyor drive digitisation partner?

TW: Innomotics is unique in the scope of our offering, from drive systems, through automation to digitalisation, so we can provide a truly integrated solution.

Our Solutions engineering teams around the world have decades of experience with conveyor systems of all types based on delivered projects as well as close cooperation with major conveyor OEM’s.

Our drive products, combined with INSPIRE IQ, offer the greatest insight into equipment operating status for predictive monitoring. Our proven DIGIMINE Digital Twin solution goes beyond traditional condition monitoring applications to support operators with concrete recommendations to improve the performance of the entire conveyor line.

MBA: Is there anything you can tell mining companies about the role of Innomotics?

TW: The Innomotics regional office in Midrand supports customers across Sub Saharan Africa in all industries with the complete range of Innomotics motors, geared motors, and Medium Voltage Drives. Our local operations include a brand new geared motor assembly facility in Midrand and a highly experienced engineering team focused on electrification, automation and digitalisation of every part of the mining value chain. We are very excited for the future of our innovative new brand, and equally proud of our long Siemens heritage.