How Multotec GV cyclones are revolutionising safe and sustainable tailings management

Lightweight, durable, and operator-friendly cyclones drive efficiency, safety, and sustainability in TSFs

Managing tailings safely and sustainably remains one of mining’s biggest challenges. For operations where above-ground deposition in a Tailings Storage Facility (TSF) is the only option, equipment must balance operational efficiency, safety, and environmental responsibility.

Many conventional methods struggle to meet stricter regulations, sustainable water use targets, and the need to manage both rate of rise and long-term TSF stability.

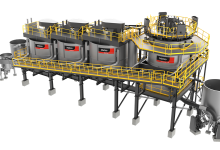

Multotec’s GV Cyclone was designed specifically for tailings dam applications. Engineered for durability, flexibility, simple maintenance, and process efficiency, the cyclone features a lightweight spin-cast steel shell lined with bonded rubber, allowing it to withstand pressure fluctuations while remaining easy to move on-site.

“By improving material distribution, Multotec’s GV Cyclones help mining operations reduce their environmental impact while maintaining safe and efficient tailings deposition,” says Ernst Bekker, Cyclone Product Specialist at Multotec.

Supporting clients with tailored solutions

A leading South African gold producer, committed to reducing environmental impact, sought a more efficient solution for slurry management. Multotec’s prior experience with the client, including extending equipment wear life, optimising cyclone performance, and supplying fit-for-purpose solutions such as screening media, samplers, and mill liners, made the company the natural partner for the new TSF order.

Overcoming operational challenges

Handling large tailings volumes under tough conditions requires equipment that is reliable, operator-friendly, and durable. Previous deployments of Multotec cyclones demonstrated performance advantages over competing systems, prompting the order for GV Cyclones at the new facility.

Innovative design for optimal performance

Multotec’s team used in-house simulations, test work, and on-site comparative trials to configure the GV Cyclones. Factors such as cone angle, spigot size, and vortex finder selection were optimised to ensure efficient operation.

“The GV Cyclones were designed with operators in mind. Features like the lightweight body, interchangeable cone angles, and quick-release spigots make day-to-day management easier and safer, while still delivering the durability needed for harsh conditions,” explains Blane Pillai, Applications Engineer at Multotec.

The cyclones deliver the optimal volumetric split between overflow and underflow to meet TSF rate-of-rise requirements. Their configuration can be adjusted as deposition conditions evolve, ensuring consistent performance even if ore characteristics change. Built to absorb pressure spikes during start-up, the cyclones also provide stability under demanding conditions.

Key Design Features

-

Lightweight construction: 44.6 kg for easy handling, installation, and maintenance

-

Durable build: Steel rubber-lined inlet head and cone with 15 mm replaceable liner for long service life

-

Quick-change spigot system: Tool-free screw coupling allows rapid replacement without shutdowns

-

Flexible operation: Interchangeable spigots, vortex finders, and cone angles (10° or 20°) for full operational control

-

Optional movable stands/skids: Simplify relocation and reduce labor requirements

Earlier in 2025, Multotec received an order for over 200 GV250 Cyclones for one of the client’s existing TSFs. Manufacturing is underway, with delivery and on-site installation support scheduled before year-end.

Delivering Results: Efficiency, Safety, Sustainability

Even before commissioning, installations at other sites highlight the benefits.

“Cyclones enable a faster, more controlled rate of rise compared to traditional open spigot deposition, reducing labour intensity, lowering operational costs, and giving operators precise control over dam wall height,” says Erick Herbst, Territory Sales Manager – Capital at Multotec.

GV Cyclones ensure even material distribution, improve water recovery, and support proper deposition characteristics, contributing to safer, more sustainable long-term TSF management.

With durability, lightweight handling, and operator-friendly features, Multotec GV Cyclones are setting a new benchmark for tailings management.

Excellent breakdown, I like it, nice article. I completely agree with the challenges you described. For our projects we started using lokando24.de and experts for our service,germanys top classified and directory growing site, well can i ask you a question regarding your article?