Global partnership boosts BME’s detonation solutions

Omnia company BME has signed a distributorship agreement for its blasting solutions business with Germany-based DynaEnergetics, further enhancing BME’s commitment to deliver future-fit solutions to its global customer base.

At the heart of the collaboration is Igneo, DynaEnergetics’ unique electronic detonator system designed for high-temperatures and reactive ground. According to BME GM Technology & Marketing Nishen Hariparsad, BME can now provide customers with solutions for very high temperature environments.

“The partnership further strengthens our initiation capability up to 150 degrees Celsius,” said Hariparsad.

He highlighted that this agreement marks the beginning of a partnership focused on extending BME’s established cutting-edge blasting technology for the mining industry.

“With a legacy of over 40 years, BME’s world-class blasting solutions and mining expertise have been at the forefront of mining industry developments in our field,” he said. “By integrating this innovative technology, we reinforce our proven capabilities in helping customers overcome their complex challenges in today’s mining operations”.

Igneo system

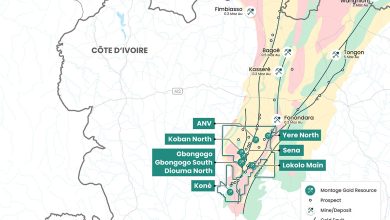

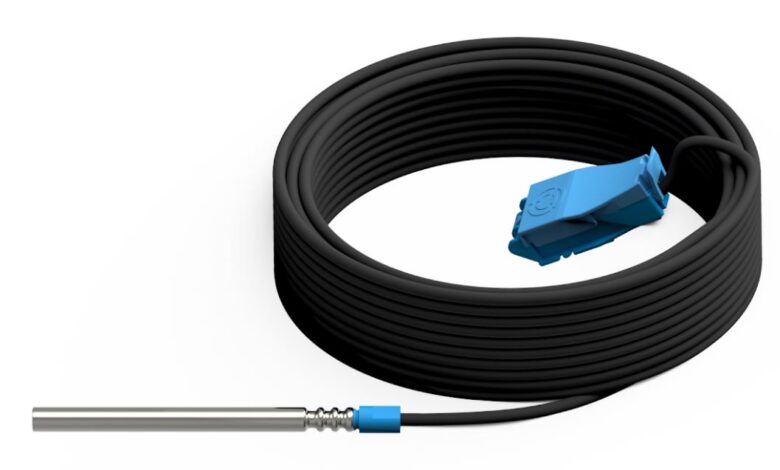

The Igneo system, developed by DynaEnergetics in collaboration with a leading global gold mining company, has been able to perform safely in the hottest open cut gold mine in the world – off the coast of Papua New Guinea. The core of the Igneo system is the HTD150, an electronic detonator designed to withstand very high temperatures up to 150°C for up to 48 hours. The device is also encased in a specially coated copper shell, making it resistant to highly corrosive mining environments.

According to DynaEnergetics’ Vice-President of Product Management Thilo Scharf, safety and innovation are at the core of this partnership.

“Together, BME and DynaEnergetics are bringing cutting-edge blasting technology solutions to the mining industry, setting new standards for safer, more efficient operations worldwide,” said Scharf.

BME’s locally developed AXXIS electronic detonation system has become a landmark feature of modern blasting practice in Africa and beyond, with the new-generation AXXIS Titanium model released in 2022.

“We look forward to further strengthening this relationship and bringing game-changing technology to the global mining sector,” said Hariparsad.

Key features of DynaEnergetics’ Igneo™ HTD150 mining detonator:

- High temperature resistant

- Programmable time delay

- Pressure sealed inside a copper shell with anti-corrosion coating

- Safe from radio frequency, stray current and stray voltage

- With the Igneo Booster Charge, the detonator can initiate loaded blast holes without the need for sensitised booster emulsions

- Initiated by the Igneo™ Digital Firing Panel, which allows the operator to test and initiate up to 1,000 detonators simultaneously

- Can be programmed and tested by the Igneo™ Programming and Testing Device