Electrostatic precipitators (ESPs) for mining projects

Electrostically clean, particulate free

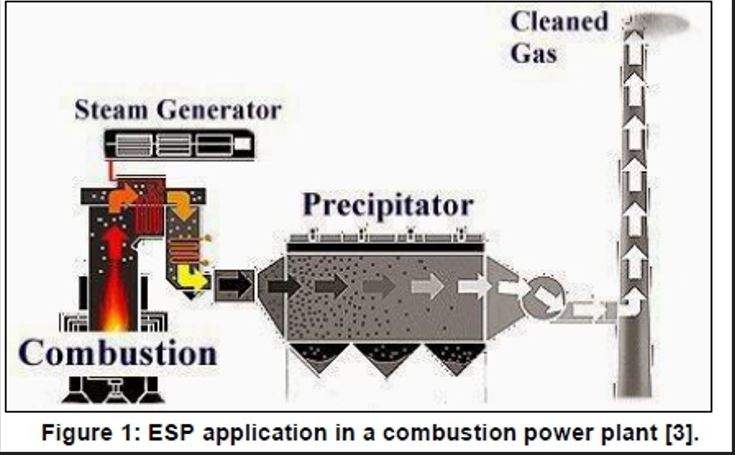

In a coal-fired power station, the use of electrostatic precipitators, together with scrubbing systems, to remove particulate matter and other contaminants minimises solvent loss, reduces maintenance requirements, and optimises energy consumption.

The reduction of flue gas emissions from processes is cardinal to contemporary mining operations, where sound ESG reporting has become centrepiece.

This is not just about tick-box environmental compliance; it is also an operating expenses (OPEX) matter. So, doubtless, mining companies should be more meticulous in the selection process of techniques they utilise to mitigate the impact of emissions.

Several options

Talking about technologies, conveniently, there are several options mines can use to handle pollutant-laden flue gases. However, it is about what could work best in their respective circumstances, as the saying goes: There is no one-size-fits-all.

Carbon emission abatement

Of course, when CO2 emission abatement is mentioned, what instantly springs to mind are scrubbing technologies. Beyond question, such technologies are effective when incoming gases are free of undesirable impurities at the inlet.

On the other hand, when the incoming gas has solid particulate matter (PM), scrubbers falls short. Thus, for an effective carbon control process, cleaning incoming gases is essential.

Electrostatic precipitators

Electrostatic precipitators (ESPs) are regarded as one of the tried and tested technologies employed to reduce PM from flue gases in off-streams and process streams in mines and other industries. One example of this application is discharging gases from a boiler steam plant in base metal and precious metal refineries.

In ESP, electrical forces remove the PM from flue gases. Typically, a high-source (discharging electrode) generating a corona current charges the PM, which migrates to the collecting plate (collecting electrode) and is removed.1

Fascinatingly, advances in technologies have made ESPs more efficient and cost effective in treating gas streams with sub-micron particulate. Where all fundamentals are properly followed, the process can achieve separation degrees of up to 99.9%, where the fundamentals are properly applied.

Wet and dry ESPs

To cater for unique requirements in projects and preferences, ESPs are available in wet and dry options.

There are some conditions in which dry separation is not possible due to the characteristics of the gas. In this case, wet electrostatic precipitators (wet ESPs) would be recommended. Generally, wet ESPs are ideal for separating the finest dust-laden water droplets and oil-containing exhaust gases, among others.

Essentially, wet and dry ESPs work on the same principle and design. However, the major difference is that mechanical rapping systems are used for cleaning the discharge and collecting systems in dry ESPs. On the other hand, in wet ESPs, due to the effect of the electric field, a film of liquid forms on the collecting electrodes that continuously drains off. 2

When is ESP a necessity?

Switching from another separation technology to an ESP would become necessary when tests indicate that a plant has PM emissions exceeding the limit. In fact, it is safe to err on the side of caution by cleaning the gas at all times, where the solids could be microns in size.

Serious implications

The presence of PM has serious implications in two areas: potential penalties due to breaching environmental regulations and increased operating expenses (OPEX).

- Environmental legislation

The removal of PM and other pollutants from flue gas is in compliance with the respective requirements of environmental management. In South Africa’s case, the National Environmental Management: Air Quality Act applies. More importantly, this is in fulfillment of the Occupational Health and Safety Act (MHSA), which obligates mines to mitigate health and safety hazards that mineworkers are exposed to. According to the World Health Organisation (WHO), PM is classified as a carcinogen. So, ESPs facilitate the provision of a safe working environment for mineworkers.

- OPEX

From an OPEX standpoint, Monoethanolamine (MEA) scrubbing systems are costly to operate on their own without effective cleaning. This specifically relates to experiences such as solvent loss, high maintenance, and high energy consumption.3

For example, in a coal-fired power station, the presence of contaminants in the inlet gas stream can result in solvent loss. Besides, they can cause fouling of equipment such as heat exchangers in the scrubber system, prompting unplanned replacements or repair costs, which escalates plant maintenance costs.

Another consideration is that the presence of impurities in the gas can result in 30 percent more power consumption in an MEA scrubbing system. In addition, ESPs overcome airflow resistance experienced in technologies like conventional bag filters, which offer resistance to airflow.

Significant difference

Generally speaking, recent experience with CO2 scrubbers in other industries illustrates the importance of the cleanliness of the gases entering a scrubber system. It has been discovered that some gases contain a high level of PM. Thus, ESP technologies present an opportunity to reduce the PM load at the inlet to a scrubber, ensuring cleaner air.

But what could work best?

Based on what providers of ESPs provide various solutions have told this publication that the main preferences of clients in mining and other sectors are low maintenance requirements and quick installation.

- Andritz Group, Dry Electrostatic Precipitators

- GEA – Electrostatic precipitator (dry and wet)

- Steven A. Jaasund of LDX Solutions, Writing for World Cement (October 2023) Inc. (Embracing ESP Technology)