Advanced blasting improves safety and provides cost saving

By significantly reducing airblast levels, Omnia Holdings company BME’s advanced blasting technologies and techniques have ensured safety compliance and saved costs at a large opencast coal mine in Mpumalanga, South Africa.

“This project has again demonstrated the interplay between regulatory compliance, cost management and blasting innovation,” said Jacques Botha, High-Tech Specialist, Africa Operations at BME.

The mine operates two primary pits where it extracts about 50 000 t of export grade coal a month using the truck-and-shovel methods.

A Section 54 notice had been issued to the mine by the Department of Mineral Resources and Energy for exceeding the 125 decibel (dB) airblast threshold at one of the pits. These operations were therefore temporarily suspended until corrective measures were implemented.

Contributing factors

Botha said Historic airblast data showed that production blasts were the main source of elevated airblast levels, often exceeding the allowable limit. While pre-split and coal blasts also contributed to higher than desired air blast levels.

Production blocks were previously configured with one or two open faces and initiated with shock tube, using a closed or open pattern. The timing sequence included a 17 millisecond (ms) inter-hole delay and inter-row delays of 42 ms, 67 ms and 84 ms.

“It proved difficult to achieve single-hole firing with the current blasting practice. The initiation system and its characteristics added to elevated airblast levels,” he explained.

He added that this was exacerbated by pyrotechnic scatter, resulting in overlapping detonation waves. In turn, there was an increase in charge mass per delay, leading to higher airblast effects.

Next generation initiation technology

To achieve precise single-hole firing, BME introduced its next generation AXXIS™ Titanium initiation system.

“The technology enabled precision design that eliminated shock wave overlaps, minimising airblast and ground vibrations intensity,” he said.

It also reduced airblast levels during pre-split blasting by eliminating the use of detonating cord. Holes were fired in clusters of five to seven per delay to control the charge mass detonated per delay.

It was determined that the main source of noise was due to the use of drill cuttings used as a stemming material.

Improved stemming

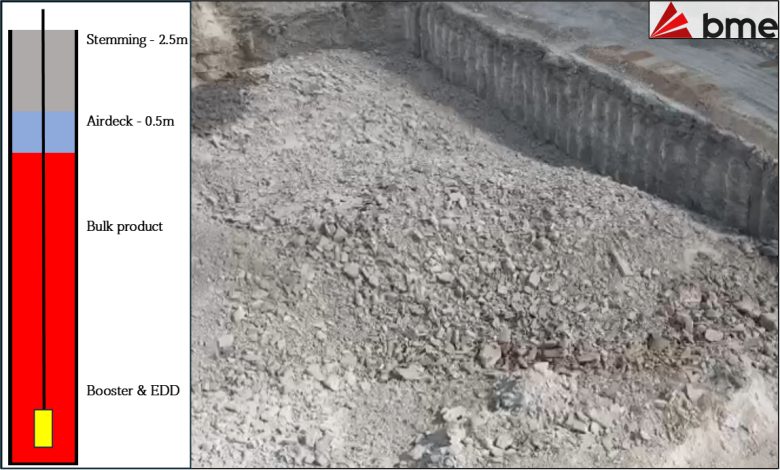

Botha said that the typical stemming length ranged between 2 m and 2,5 m, with beneficiation plant discard used as a stemming material.

“Shorter stemming lengths were used where competent sandstone extended from the collar to the toe,” he said. “This sandstone type is notoriously difficult to fragment, particularly in the collar zone where excessive stemming leads to oversize.

Using the Scaled Depth of Burial (SDOB) ratio as a guideline, the stemming length was increased to 3 m for a 1,104 m/kg¹/³ SDOB, which is aligned with the controlled energy range.

“We also introduced graded aggregates as a stemming material to enhance control,” he said. “We introduced a 0,5 m air deck to achieve the desired fragmentation within the stemming region, thus mitigating the oversize material risk in the collar region.”

For pre-splitting, BME placed a stemming plug at 1 m and used drill cuttings for stemming to minimise airblast levels. Meanwhile, a stemming plug was placed at 2,5 m and drill cuttings also used as a stemming material for coal blasting.

Blasting cost management

Botha said that by further optimising stemming length, burden and spacing of blasts, BME also reduced explosives consumption.

“Originally, the mine used a staggered blasting pattern of 4 m by 4 m, with 165-mm diameter holes with an average hole depth of 21 m,” he said. “This pattern was later expanded to 4.5 m by 4.5 m to further optimise cost savings.

He noted that more than R590 000 was saved on a 150 m by 35 m block of 21 m in depth. In addition, fewer holes had to be drilled on a similar size block, resulting in a 21% increase in drilling efficiency.

“The mine has the option to extend the blast by an additional 27 m by 35 m to realise an effective free blast for every 5 blocks blasted,” he said. “By improving drilling efficiencies, coal can be exposed faster – which boosts production.”

Following these interventions, BME’s customer reduced overall airblast levels by 83% and further avoided disruptive conditions impacting their operations. “By empowering our customer with optimised solutions, we support and partner to ensure safety standards are maintained, and operations are effectively supported”, he said.