Packaged filtered water treatment plant

WEC Projects: Largest packaged filtered water treatment plant

WEC Water has been in the water and wastewater treatment business for over 20 years and has completed over 400 projects, so when they achieve a major milestone, it is usually worth celebrating.

The latest addition to WEC Water’s already impressive reference list is a project that really tested the boundaries of what was thought possible in packaged water treatment. WEC Water provided a seamlessly executed turnkey project to fabricate, deliver and commission their biggest ever packaged water treatment plant to a difficult to reach mine in the Democratic Republic of Congo.

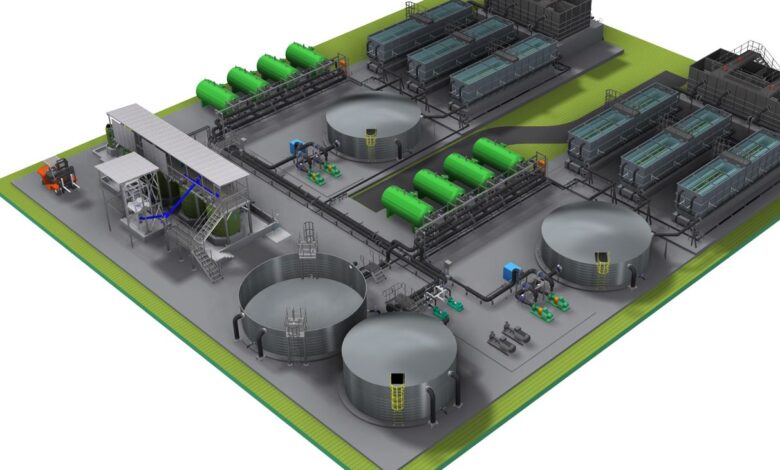

The mine needed a water treatment plant that can treat 680m3/hour from the processing plant to reduce the risk of water insecurity on operations and the mine’s overall water use footprint. Adding to the complexity for this plant was the variable quality of the influent water, the remote site location, and the specifications that the mine requested to maintain the highest level of safety on site. As a final consideration, the client wanted to keep the civil requirements to a minimum to reduce on-site installation time.

WEC Water’s team of specialist Process and Mechanical engineers came up with a packaged plant design that ticked all the boxes for the client. They designed a system with two treatment trains each consisting of a flocculation tank, three clarifiers, four multimedia filters, and intermediate storage tanks. The plant was designed to be modular so that it could be fabricated in South Africa and delivered to site in a remote region of the DRC with relative ease.

This plant represents the biggest packaged water treatment plant that WEC Water has ever designed but that didn’t bother the execution team. They managed the delivery, installation supervision and commissioning with excellence and ensured that the plant was handed over to the client on time and fully operational. Nigel Birchall, a WEC Water Project Manager, credits the success to meticulous planning and implementation of critical elements to the client’s specific requirements.

“One such consideration was for the plant to use as little liquid chemical as possible” explained Birchall. “It is difficult and expensive to get liquid chemicals to remote sites, and it creates an unnecessary health and safety risk. To address their concern, WEC Water designed the plant to use dry chemical make-up equipment allowing precise dosing through the automated system without the need for liquid chemical sourcing and handling.”

Logistics creates other challenges in delivering a plant like this. The coordination of the packing, loading, and delivery were critical to ensure that all the parts on all the loads – 18 super-link trucks worth – were delivered to site in good working order. Meticulous planning was done to orchestrate the logistics, and constant management and communication allowed for everything to arrive on site in time. It was a monumental cross-functional effort between the teams on the ground allocating, packing and loading the goods, to the logistics coordinators and transport companies and the teams on the ground in DRC unloading and installing the plant.

This plant is a feather in the cap of the WEC Water team and adds to their already impressive list of references. With successful installations in more than 20 African countries, WEC Water has proven their capability to get their projects completed despite the various challenges associated with working across Africa. In reflecting on this project, Tim Fischer, Process Engineering Manager at WEC Water, said: “This project gave us all some grey hairs and kept us up a few nights, but this is what we come to work to do – Engineer the water of tomorrow. We look forward to the next challenge – the next opportunity to do something extraordinary – so get in touch and let us find a solution to your unique water treatment challenges.”