Digitisation has simplified the tedious task of conveyor system management, resulting in tangible benefits. These are primarily in the form of increased efficiency, reduced downtime, and improved safety.

Availability, efficiency, and safety are the most desired aspects of conveyor performance systems in contemporary mining. However, due to exposure to extreme temperatures and other adverse conditions, achieving these goals using conventional techniques can be challenging.

Digitisation

Fortunately, technological advances provide an innovative solution. Increasingly, digitisation is emerging as a tool for optimising conveyor system performance. Results from mining projects, where digitisation is incorporated in conveyor design, show marked improvement. Typically, digitisation involves the integration of automation, robotics, and artificial intelligence.

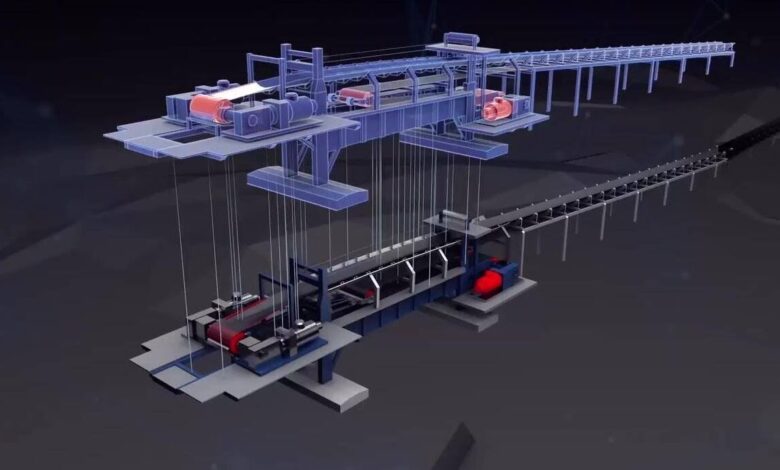

Digital twin

As part of digitisation, a digital twin, a virtual replica of the conveyor system, is created. Florian Huthmann of ThyssenKrupp Mining Technologies, who has been involved in conveyor digitisation projects and has done extensive research in the area, has documented his findings (The digitisation of the conveyor). He offers a more precise description of a digital twin: “The digital twin refers to a complete digital representation of a physical asset. It includes its design specifications and mathematical models, as well as as-built and operational data unique to the specific asset it represents. With the latter, it is ensured that design and reality are in scope.”

Monitoring, analysing, and predicting

Basically, a digital twin can help establish whether the conveyor system operates within design specifications. Through real-time data and insights from the digital twin, the plant engineer can monitor, analyse, and predict the performance of the belt conveyor in real-time. In this way, ultimately, it can facilitate the following:

- Operational efficiency

Digital twins can help determine whether optimal tonnage can be attained with the existing design or if the system must be modified. Huthmann explains where digital twins would be key: “Conveyors may be over-designed for their intended use, and rather than investing in what is perceived to be a necessary and costly modification, digital twins allow for tests and optimisation.” He cites the example where Thyssenkrupp’s digital twin helped a customer handle 30% more throughput without mechanical modification.

- Predictive maintenance

A digital twin allows for early anomaly detection in the conveyor’s performance. With the data gathered from this exercise, a predictive maintenance strategy can be mapped out. “The 24/7 monitoring of a conveyor system can easily pay for itself, detecting faulty parts, incorrect installation of spare parts, or rare black swan events,” Huthmann states, ultimately time-consuming and costly or catastrophic failures can be avoided.

Besides, where failure has occurred, a digital reconstruction of a conveyor system reconstruction can allow for a thorough root-cause analysis.

- Safety

A digital twin can highlight operational variables that must be changed to enhance safety.

- Reducing OPEX

Energy accounts for one of the highest percentages of conveyor systems’ OPEX. By allowing for an increase in the conveyor system’s efficiency, a digital twin could reduce the power draw. This could contribute to a significant reduction in OPEX. What’s more, there could be a wide scope of other gains.

Revolutionalising conveyor management

By and large, digitisation is revolutionising conveyor systems management in ways previously deemed impossible. With Industry 4.0 becoming part of the machinery DNA, digitisation will open many opportunities and enhance numerous key performance metrics. Indeed, there are enormous dividends from the adoption of digitisation.

Sidebar

Components of a conveyor digital twin

Typically, a conveyor digital twin has the following components:

- Software

The first is software, which accommodates critical parameters such as ambient temperature and topography. For existing conveyors, these are drive power, pulleys, belt length and width, pulleys, etc.

- Data

The second one is managing data. Data is obtained in two ways: either from a single data dump for once-off health checks or live data from the asset itself from the conveyor. In this context, data includes load from belt scales or power draw.

- Calibration

The third one is calibration. The digital twin is calibrated to ensure that it is the same model as the physical conveyor. For instance, projected power demand is equal to the physical system.

- Evaluation

Finally, once good to go, the digital twin can be used to evaluate whether the conveyor system is operating according to expectations.