Custom Chutes show their mettle with abrasive ore

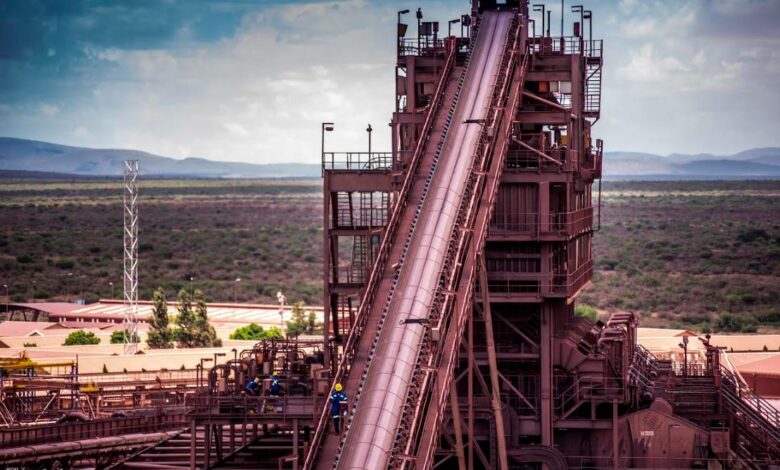

With most of its 5,000-strong global footprint of transfer chutes being installed in Southern Africa, Johannesburg-based Weba Chute Systems has built a reputation in demanding mining conditions.

The region is a leading producer of platinum and manganese, for instance, which are both highly abrasive ores, points out Dewald Tintinger, Technical Manager at Weba Chute Systems. The company’s innovative approach and customised designs control material flow and resist wear, matching specific site conditions.

“First and foremost, a chute must facilitate optimal throughput so that mining production is not hampered by frequent blockages or repairs,” says Tintinger. “It is well known that the cost of a quality chute is a fraction of the cost of lost production through downtime.”

Systematic approach

He highlights that Weba Chute Systems takes a systematic approach to assessing each customer’s requirements, starting with the general arrangement of the area around transfer points. The depth of experience accumulated over 40 years in business allows the company’s experts to suggest improvements to the layout – where these are possible and where they affect the chute performance.

“Then we consider a range of key factors like the material characteristics, the throughput tonnages and speed of travel, when we plan the design,” he says. “These considerations guide the application of our controlled flow philosophy.”

The design is built on scientific calculations using the anticipated trajectories, impacts and pressures on the structure. The main conceptual options are Weba’s Cascade Chute with dead boxes, the Weba Superflow chute with liners or a combination of both.

“A key element of our popular Cascade Chute is the use of dead boxes and lips on the inside of the structure, which traps material and allows other material to flow over it,” says Tintinger. “This ensures that up to 70% of the wear surface is protected by stationery material, which substantially reduces wear and maintenance costs while extending service intervals.”

As material enters the chute and flows through, it lands mainly on other material which absorbs the impact more effectively, protecting the underlying wear plates and structure from undue damage. This also reduces dust creation, he notes, which is an ongoing health and safety concern on mines.

“Controlling material flow through the right chute design also protects costly equipment like conveyor belts,” he says. In one example, Weba Chute Systems installed a cascade chute at a Southern African copper mine to better control the flow of material onto conveyor belts. This saved immediately on belt costs – while boosting productivity through improved uptime.