How to OBTAIN™ Improved Throughput and Sorting Precision

Hard on the heels of the groundbreaking launch of OBTAIN™ at the Investing in African Mining Indaba, Stefan Jürgensen, Software Team Leader at TOMRA Mining, fields questions from Mining Business Africa. In the interview, he elaborates more on the value OBTAIN™ will add to X-RayTransmission (XRT) single-particle sorting tasks in mining, and underlinesTOMRA’s commitment to supporting mining companies interested in the software.

MBA: On their own, TOMRA’s flagship X-Ray transmission (XRT), Near-Infrared (NIR) and Laser sensor-based sorting technologies ostensibly have been working perfectly, breaking milestones in recovery. Why has TOMRA decided to tap into deep learning through OBTAIN™?

SJ: TOMRA is continuously evaluating new technologies that can further advance sensor-based sorting. We strive to offer the most sensitive and robust sensors, the most energy-efficient and precise ejection systems, and the most advanced and reliable data processing technology. Although the current hype about large language models directs the most attention to human interaction with AI, there are unique features of the Deep Learning approach that perfectly augment our current XRT sorting technology to enhance throughput without compromising sorting quality. OBTAIN™ adds an extra layer of intelligence.

MBA: Does the introduction of OBTAIN™ suggest there are inherent limitations with the capabilities of AI-powered XRT, NIR and Laser sorters? Please elaborate.

SJ: Innovation is a continuous journey: over the past three decades, TOMRA has been at the forefront of developing cutting-edge sorting solutions for mineral processing. Every new generation of sorters has built upon the foundation of its predecessors, incorporating advancements in technology, efficiency, and accuracy. With the introduction of OBTAIN™, we are once again pushing the boundaries of what is possible in sensor-based sorting. We are maximising resource utilisation and promoting sustainability.

MBA: Demonstrate how the software, through data from deep learning, can bring single-particle precision to high-throughput particle sorting.

SJ: Single-particle sorters generally need not consider the interaction between neighbouring particles in material streams. This approach allows for precise analysis of each particle’s properties and can increase the accuracy of the sorting decision, but at the cost of a throughput suitable only for laboratory-scale applications. With OBTAIN™, TOMRA bridges the gap between precision and throughput. We use Deep Learning to apply knowledge about particle characteristics that enable the same type of analysis used for single-particle sorting at throughput rates of tens of thousands of particles per second, even when particles are clustered.

MBA: We notice that, despite the hype about AI, which is almost akin to religious fervour, TOMRA has been leveraging this ground-breaking technology since 1993. How does this experience help TOMRA’s R&D team when devising solutions?

SJ: Artificial Intelligence (AI) is a vast scientific domain, with numerous conferences each year, even for small subtopics within the field. Like most technologies, AI lacks a universal “Silver Bullet”; instead, there are many different approaches for its implementation and utilisation. Furthermore, today’s sensor-based sorters feature sophisticated multi-staged data processing pipelines.

TOMRA’s substantial experience in the field of AI and its application to sensor-based sorting, and the collaboration of our teams of experts allow us to select the most suitable AI technology for each part of our processing pipelines. OBTAIN™ represents the convergence of cutting-edge technology and decades of expertise.

MBA: How does a mine incorporate OBTAIN™ into its existing TOMRA ore sorting process? How is the team responsible at OBTAIN™ involved?

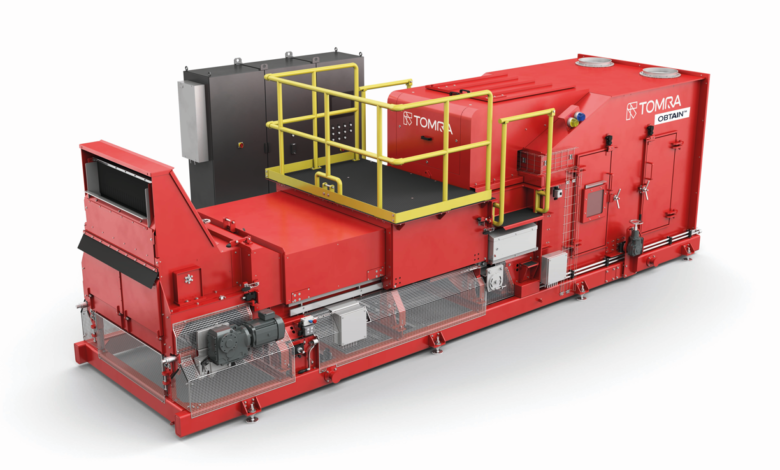

SJ: TOMRA assesses the benefits of using OBTAIN™ for the mine’s sorting needs and offers OBTAIN™ upgrade packages if they are advantageous for the mine. These packages enable seamless integration of OBTAIN™ into the mine’s existing COM XRT sorters. The process of installing OBTAIN™ is straightforward and can be carried out by any trained TOMRA Service technician. All new COM XRT sorters are ready for OBTAIN™ as an optional feature.

OBTAIN™ can improve the performance of TOMRA’s COM XRT sorters in throughput and sorting quality. The achievable improvements depend on many factors like the feed stream’s PSD and other site-specific requirements. Therefore, we recommend getting in touch with our Sales representatives. In our Test Center, we can determine in which way OBTAIN™ can be put to best use for each COM XRT sorter.

MBA: In a nutshell, how do mining companies benefit from adopting OBTAIN™ in sensor-based ore sorting processes?

SJ: By implementing OBTAIN™, mining companies achieve consistent performance from sensor-based ore sorters across a wide range of throughput. This flexibility allows them to either process more material or improve sorting quality. Additionally, the statistical data collected from the sorted material streams becomes more accurate.

MBA: Last but not least, TOMRA always sees a lot of opportunities in the African mining sector. What are your plans to serve this lucrative market with revolutionary sensor-based ore sorting technologies in 2024?

SJ: At TOMRA, our commitment is to deliver top-tier sorting technology to the African mining industry. We continually strive to innovate in sensor-based sorting, and we are already preparing to unveil exciting new features.