Heatless Pressure Swing Air dryers & Compressed Air Instrumentation

Artic Driers has over 30 years in the air treatment business.

Compressed air quality is an issue in most organisations, and in many cases, it’s a neglected topic. Contaminated compressed air (C/air) is as bad as no compressed air!

Solutions

Two products offer solutions to these air quality problems, the SAHARA range of low dewpoint heatless pressure swing air dryers and the SUTO iTEC compressed air instrumentation.

SAHARA SERIES AIR DRYERS – Artic Driers manufactures the range of Sahara low dewpoint Heatless Pressure Swing Air Dryers at their base in Johannesburg to SANS 347 codes. Designed to be desiccant-rich, pressure dewpoints of minus 40°C are standard.

The build standard & specifications are to a high standard. Smaller dryers are free-standing, whilst bigger capacity dryers are fabricated on a heavy-duty baseplate.

All the dryers are designed to be transported in a standard container, making it ideal for shipping into Africa. If required, pre & after filters may be fitted to the dryer’s baseplate prior to despatch.

The Sahara units all use the Artic RSA patented shuttle valve & orifice plate holder. The Shuttle comprises only 4 items and provides the highest reliability in a wide range of service/site conditions.

The standard Sahara dryer has only two pneumatically operated dump valves. This reduces the maintenance requirement and makes any fault finding a breeze.

If needed, the dryer’s control timers can be adjusted on-site. Sahara dryers may be equipped with an optional dewpoint control, as well as pressure & flow monitoring. Dewpoint control reduces the c/air purge requirements and extends the cycle times of the dryer. On larger air dryers all the electrics are housed in an IP65 cabinet.

Power Outages creating re-start problems – Sahara dryers re-start automatically on the resumption of power.

Huge range of ex-stock filter casings – Artic Driers provides a huge range of imported & locally produced air filter housings that can hold different grades of filter elements to suit any client’s requirements. Locally produced filter casings are SANS pressure-coded & are coated to resist interior & exterior corrosion. All the element fixings are s/steel. Artic carry stock with capacities up to 150 m³/min.

If you need a tough versatile filter dryer package for your plant, call us now.

Need to know more about your compressed air consumption?

A broad range of instrumentation focused on compressed air & gas monitoring for volume, pressure, power consumption and c/air quality is available from SUTO iTEC & Artic Driers.

Flow monitoring equipment is suitable for pipelines from 15 mm to > 400 mm and compatible with most gases with pressures from vacuum to over 40 bar G.

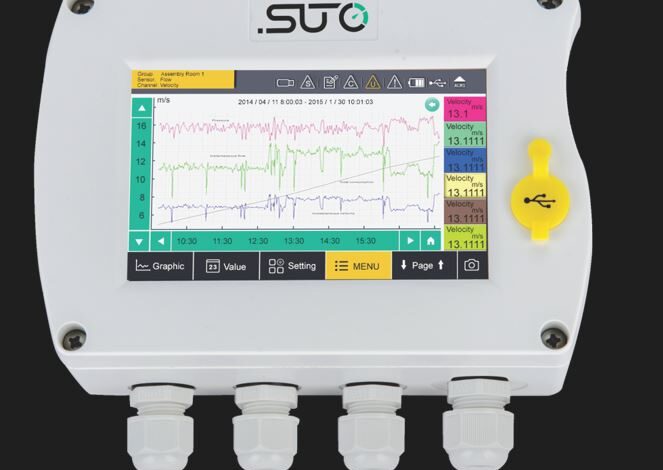

Adding an S331 data logger can provide plant operators and managers instant access to all the parameters, flow, pressure, dew point, temperature, power consumption, oil vapour content as well as particle content.

When coupled to the local data network it will transfer all the information to the central management system in the plant. Data transfer from the S331 data logger to a USB stick is also provided.

These SUTO iTEC products give an instant overview of your plant’s consumption and quality parameters, making benchmarking consumption & c/air quality simple.

Air leaks causing production cost issues? Artic Driers International, SUTO iTEC’s Southern Africa partner, offers an Ultrasonic leak detection solution. The reporting software provides immediate information on the cost of c/air wastage, and the the volume of air being wasted to the atmosphere. Results are provided in PDF & Excel (csv) format which allows you to plan your rectification programs. Artic offers this equipment for sale, or hire with one of our technicians.

Compressed air quality a problem? The SUTO iTEC S600 certified mobile Air Quality System has the solution measuring dew point, airborne particle sizes as well as oil vapour carry-over. It automatically creates a PDF report that rates your test results against the ISO standard without any input requirements from an operator. Air quality reports are generated before Artic leaves your site. This is exceptionally useful for QA & facility managers alike.

Leaders in the air treatment business for over 30 years, Artic Driers has an exceptional range of equipment, along with in-house manufacturing capabilities. This makes Artic Driers a “Preferred Supplier” to solve your compressed air problems. With a large warehouse inventory, we rarely disappoint.

Call us now with your requirements on 011 420 0274 and speak to our sales team for more information.